Foodborne illness remains a significant problem in the United States. The Centers for Disease Control and Prevention estimates that 48 million people get sick, 128,000 are hospitalized, and 3,000 people die from foodborne illnesses in the United States every year. Biofilms are one of the insidious culprits behind these illnesses. Biofilms thrive in moist, nutrient-rich food production environments. Moreover, biofilms are naturally resistant to many of the typical sanitation strategies used by food manufacturers.

Foodborne illness remains a significant problem in the United States. The Centers for Disease Control and Prevention estimates that 48 million people get sick, 128,000 are hospitalized, and 3,000 people die from foodborne illnesses in the United States every year. Biofilms are one of the insidious culprits behind these illnesses. Biofilms thrive in moist, nutrient-rich food production environments. Moreover, biofilms are naturally resistant to many of the typical sanitation strategies used by food manufacturers.

As a result, it’s critical that food production organizations have a clear understanding of biofilms and effective tools for sampling their environment and proactively identifying these risks.

What are biofilms?

Biofilm is a microbial community that forms on a surface in a moist environment. The microorganisms of this community produce a sticky substance, creating a nutrient rich microenvironment. Once established, biofilm protects its resident microbes from drying out and from antimicrobial agents such as disinfectants and even treatments such as heat and UV radiation.

Biofilm can become a stubborn problem—particularly as these disinfectant-resistant microbes may include infectious pathogens.

The biofilm life cycle

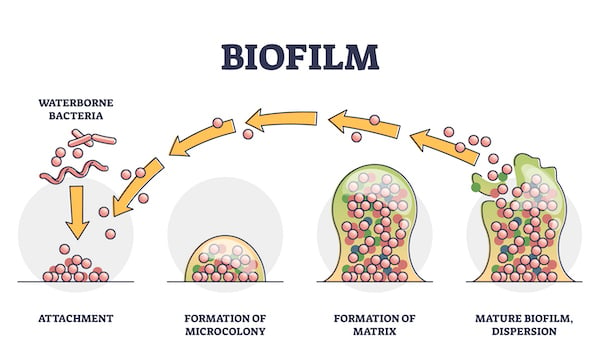

Biofilm development can happen fast, often within a few days. This life cycle occurs includes five stages:

- Surface growth begins when certain bacteria settle on a surface.

- A monolayer is formed as bacteria clump together and attach to one another on the surface.

- A multilayer microcolony begins to form as bacterial cells grow and divide.

- As the biofilm matures, it strengthens its three-dimensional structure and gains greater protection against attacks.

- Once it achieves critical mass, a portion of the biofilm dispenses to release more free floating cells to other areas.

As these free-floating microorganisms disperse, the biofilm formulation cycle repeats itself.

How is biofilm impacting the food supply chain?

Biofilms present a particular challenge in the food production and services industries. These facilities’ operations rely upon drains, pipes, freezer coils, food processing equipment, and other difficult to reach areas that provide the conditions in which biofilm thrives. As this biofilm grows, it becomes a reservoir for pathogens that can lead to disease outbreaks. Pathogens commonly found in food packaging plants include, Bacillus cereus, Escherichia coli, Listeria monocytogenes, Salmonella enterica and Staphylococcus aureus. To reduce infection risks, it is critical to take proactive measures to prevent biofilm formulation and break potential routes by which infectious microorganisms are transmitted from biofilms to people.

The challenge is that biofilms are largely resistant to typical cleaning agents and strategies. For example, the bacteria Listeria monocytogenes – which caused outbreaks in the 1990s in deli meats and hot dogs and is now often linked to dairy products and produce – can persist on food contact and non-food contact surfaces even after aggressive cleaning.

Regulations managing these food-related environments have focused on the need to eradicate specific foodborne pathogens, and less so on the biofilm that may protect these organisms. However, every food production organism should have a plan that begins with strategies for preventing biofilm, includes steps to eradicate it, and ensures safety through regular testing.

How to prevent biofilms

Preventing biofilms begins with good hygiene design, well-maintained equipment, and effective maintenance processes. With regards to maintenance, cleaning – i.e. removing debris – is a critical first step for removing much of the contamination that makes disinfection ineffective. From there, it is best to use a combination of strategies to ensure biofilm removal is effective.

- Identify: It’s important to know which areas may be prone to biofilm development. These moist, nutrient-rich areas should be tested regularly.

- Time: Biofilm development happens fast. With timely sanitation, you can prevent this buildup before it’s established.

- Action: Aggressive scrubbing can help break down biofilms’ sticky exopolymer and lift it from a surface.

- Chemicals: Not all cleaning agents are able to penetrate a biofilm’s structure, so talk to your sanitation chemical providers for the most effective solution for your needs. For maximum impact, chemicals must be applied and left in contact long enough to be effective and then thoroughly rinsed from the surface after use.

- Temperature: Some evidence indicates that heating a surface to at least 265 degrees Fahrenheit may be effective in breaking down biofilms, but not all materials and equipment in a food facility cannot be heated to the necessary temperature.

What is an environmental sampling kit?

An environmental sampling kit provides all the tools needed to identify the presence of potentially harmful microorganisms or verify that sanitation efforts have been effective. These kits are often tailored to address specific risks, so it’s important to understand which pathogens are most likely to occur in your food production environment.

What are the components of an environmental sampling kit

ESK® environmental sampling kits are contained within a quick-peel package that eliminates the risk of contamination prior to sampling. Inside is a 4- or 10-ml vial with a quick-turn, leak-resistant cap. A polyester-tipped swab remains attached to the cap for ease of use. The vial will also contain one of four medium options, each with a specific use:

- Neutralizing Buffer

- Buffered Peptone Water

- Letheen Broth

- Butterfield's Solution

Tips for choosing the right environmental sampling kit for biofilm identification

Is it important to select an environmental sampling kit product with the medium best suited to your needs.

- Neutralizing Buffer has the ability to inactivate the bacteria and the bacteriostatic effect of chlorine as well as quaternary ammonium compounds. This means after cleaning surfaces and food equipment with disinfectants, swab samples are taken to examine the effectiveness of the disinfectants. Neutralizing buffer medium neutralizes the antibacterial effect of such disinfectants on the swabs, thus allowing the bacteria to survive if they are present.

- Buffered Peptone Water is used for the identification of salmonella. When salmonella species are present in food, certain food processing conditions such as heat, desiccation, preservatives and pH changes may injure bacteria cells. A pre-enriched buffered peptone water medium allows these injured cells to repair for easy identification.

- Letheen Broth allows manufacturers to determine the effectiveness of their cleaning program by taking swab samples of cleaned equipment. Letheen Broth medium neutralizes any surface disinfectants, chlorine, or fluorides to create an environment in which bacteria may grow in order to identify whether bacteria remains after disinfection.

- Butterfield's Solution is used for dilution and enumeration of microorganisms in water, food and dairy products. When the number of bacteria in a sample is too high to effectively count, serial dilutions are prepared in tubes containing Butterfield's Solution.

The benefits of finding the right biofilm sampling swab

While the sampling medium is a critical component, it is also important to use an appropriate swab, with superior elution capabilities. Your swab may need to provide a large surface area for the capture of enough organisms to accurately identify the contaminant, or may need to be able to access difficult to reach areas.

Ensuring the right tools for your application is one reason that Puritan provides environmental sampling kits. However, we’re happy to answer any questions or help you find a more suitable tool for your task. Contact us anytime or find additional resources at our Food Safety Portal.