Consider the swab – it has been around for less than a century. It began quite simply in 1923 as the inspiration of a Polish-American named Leo Gerstanzang. Today, the swab is no longer a simple tool but rather a broad range of tipped applicators, used for everything from patient care and microbiology, to forensics and research, to industrial cleaning and food production.

Puritan Medical Products dates back to 1919, before the documented birth of the swab (back then, we had a different name – learn more about our history here.) A US manufacturer that produced single-use items, the company’s product line soon grew to include the Puritan® brand cotton-tip applicator. Commonly called a “swab,” this tool has been the gold standard for tipped applicators used in patient care ever since.

Evolving with Markets

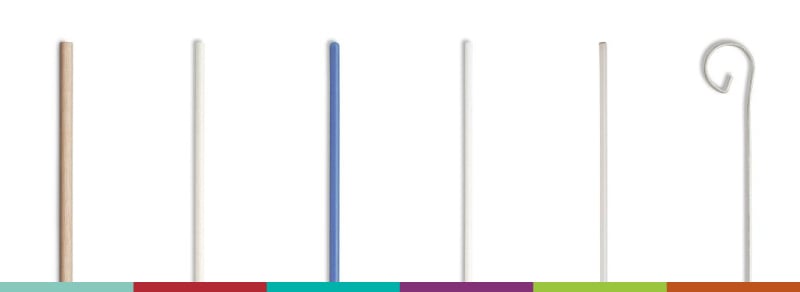

Swabs have not been limited to the early design. On the contrary – they have taken on many looks to serve every industry and application. Recognized as a simple, user-friendly tool, the swab has proven indispensable in every medical practice, hospital, and lab. Today, swabs come in a broad range of configurations of size, shape, and material. Shafts may be wood – like the first ones produced – or plastic, such as polystyrene or polypropylene. Paper and wire are also used as swab shafts.

Swab tips were first made of cotton, for its cleanliness and absorbency. It is an economical, US-sourced material commonly used in cleaning applications. When sterilized by ethylene oxide (EtO) or autoclave, cotton swabs become the universal tool for use in a healthcare setting. Cotton has also been widely accepted for DNA collection in forensics.

Synthetic-fiber swabs are used for specimen collection where natural materials are not suitable. Rayon, a fiber made from highly processed wood, is classified as synthetic. This fiber offers the properties of softness and absorbency similar to cotton and is commonly used in diagnostic applications.

Dacron® spun polyester from Dupont was introduced to the diagnostic market. Commonly used where a synthetic fiber is needed, polyester fiber collects material on the surface of the tip – it does not absorb the specimen – allowing for efficient release of the specimen for assay. It is widely used in lateral flow point of care treatment (POCT) for this reason. Polyester-tipped applicators are used in every area of diagnostics. They are also found in environmental testing systems.

Polyurethane foam was introduced for collection and dry transport of specimens. These tips work well for specimen collection. You’ll find these applicators in POCT kits for respiratory infection. Foam is also widely used for the collection of DNA, especially buccal cells. This material readily collects cellular material on the tip surface for reliable transfer.

Use of Specialty Foams Broadens Possibilities

Surfaces in a food processing plant or at an environmental hazard site can be tested for contaminants with stable and readily available foam materials. Foam can be made in many shapes allowing for easy customization. Foam can be used to tip handles that are slim or flat, long or short and is available in a range of thicknesses and porosities. And tipping with specialty foams that offer other properties broadens possibilities. Some foam-tipped applicators are fabricated by a process that does not require adhesive, eliminating the possibility of depositing residue on the surface being tested or cleaned.

Tips of knitted polyester or microfiber are very absorbent, can be small or large, are very clean and leave very little particulate behind. They are ideal for use in controlled environments as in the manufacture of medical devices and the maintenance of equipment – so they are chosen for specialty cleaning applications in lab and industry.

Flock-tipped applicators utilize short, synthetic fibers rather than spun fiber. Flock technology was initially developed for cosmetic and industrial applications. Now, used in the manufacture of a tipped applicator, the flock swab is considered by many to be the optimum device for collection and release of microbiological specimens. These tips are also proven to be most efficient for specimen collection and release of molecular specimens, and they have been specified for DNA collection in forensic and genomic applications. Bi-component, multi-length polyester fibers, are used in the production of Puritan’s patented PurFlock Ultra® and HydraFlock® swabs.

The Swab as a Transport Media Device

The story of the swab doesn’t end with the tipped applicator. To many in microbiology, a “swab” is a transport media device for collection and transport of a microorganism to the lab. Puritan now offers these products as well. Formulated in Puritan’s production lab, this line brings these essential tools to hospitals, public health agencies, and USDA and FDA labs. For researchers in genomics, PurSafe® preservation solution reliably transports molecular specimens.

When the search is for a bacterial or viral infection, transport media packaged with or without swabs facilitate collection and now, thanks to the development of commercially available processing systems, the assay can be accomplished through automation.

For instance, Puritan’s LA-116, a liquid Amies medium product, has been proven to work well with the familiar WASP automated processing system. The same holds true for the Cary Blair medium when used with the BD Kiestra. Studies that go into detail can be found at our website.

Conclusion

From basic to automation-ready, the swab will continue to evolve to address the needs of innovators in microbiology, genomics and other areas of investigation. Follow us as we keep pace with emerging technologies.

Puritan continues to manufacture all Puritan brand tipped applicators and specimen transport devices in Guilford, Maine. For details on products, please visit www.puritanmedproducts.com. For samples and product support, please contact our sales team at sales@puritanmedproducts.com.